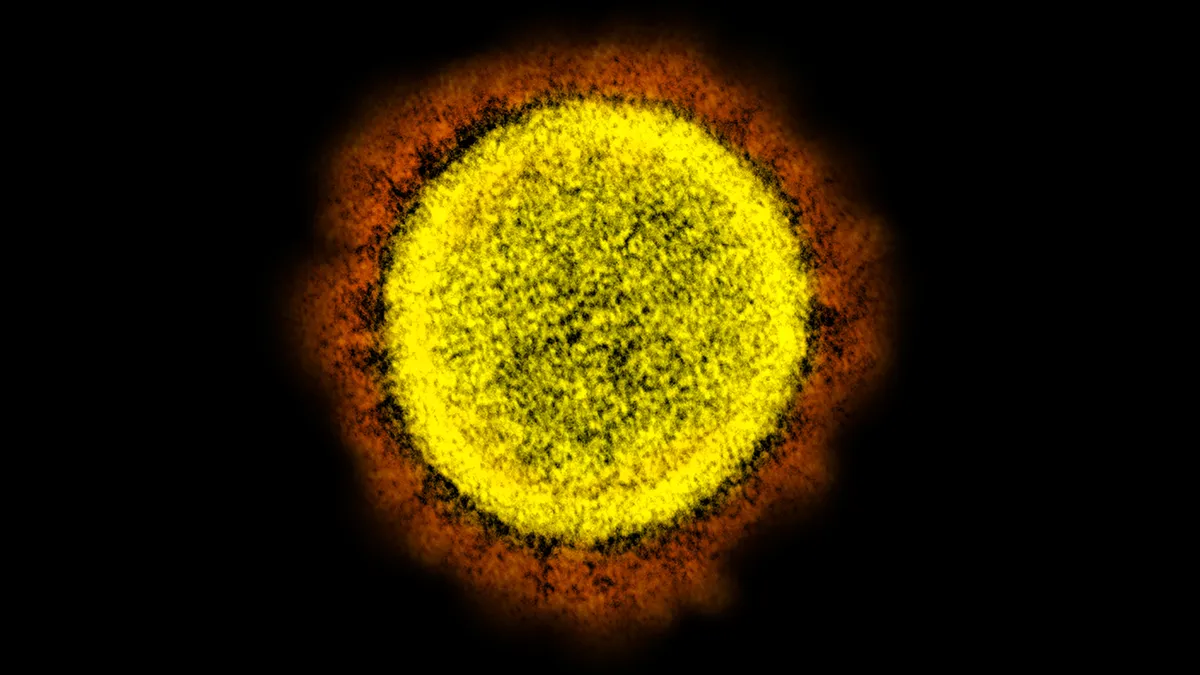

Hospitals fighting the novel coronavirus are not only experiencing shortages of ventilators and personal protective equipment but also of infusion pumps critical for providing medications and fluids to the growing number of hospitalized COVID-19 patients.

The Institute for Safe Medication Practices, an affiliate of the nonprofit ECRI Institute, in recent weeks reached out to all major manufacturers of infusion pumps and hospitals to assess supplies of equipment and drugs. Its conclusion: "people are having trouble getting enough pumps," Michael Cohen, ISMP's president said during a webcast last week.

"Some organizations are already experiencing unprecedented shortages of smart infusion pumps and dedicated administration sets, while others are still anticipating such shortages," according to an alert issued by the nonprofit on how to manage the delivery of drugs amid pump scarcity.

Recognizing increased demand for infusion pumps, FDA on April 5 issued guidance aimed at spurring access to the devices for patients infected with COVID-19 who "may require continuous infusion of medications, nutrition, and/or other fluids.”

The goal is to give more flexibility to infusion pump companies to address manufacturing limitations and supply shortages related to the public health emergency.

Susan Niemeier, chief nursing officer for infusion pump maker Ivenix, is concerned that infusion pumps will be even less available as hospitalizations for coronavirus increase.

With much attention focused on shortages of ventilators and PPE, Niemeier says the healthcare system must take a "comprehensive look" at what it needs to care for the surge in COVID-19 patients, especially those on ventilator assistance who require IV support.

"While a patient is on a ventilator, they're often placed on a number of drugs," according to Niemeier. "Infusion pumps aren't talked about a lot but they are another necessary medical device for treating these complex patients."

Rebecca Stolarick, corporate vice president of regulatory affairs for infusion pump maker B. Braun Medical, said the main advantage of the FDA’s COVID-19 guidance is that manufacturers with pumps already on the U.S. market can make low to moderate risk changes to the devices without submitting a new 510(k).

According to the FDA guidance, changes to the pumps could include a modification in design, intended use, material, chemical composition, energy source, or manufacturing process.

Creating distance between providers, patients

The FDA's guidance also seeks to promote tech like remote monitoring of infusion pumps so providers and COVID-19 patients can maintain safe distances from each other.

While hospitals are not yet remotely managing these devices, they are putting infusion pumps in hallways, rather than in patients' rooms, and using long tubing to help reduce nurses' exposure to the virus and conserve PPE. Extension sets enable hospitals to run that tubing under doors and sometimes through makeshift holes in walls.

B. Braun, one of the biggest makers of infusion pumps, has developed its own guidance to support hospitals placing infusion pumps outside patient rooms with the extension sets to help clinicians “ensure safe and effective delivery of fluids and medications,” according to Angela Karpf, corporate vice president of medical affairs.

However, ISMP contends the use of long extension sets can affect infusion pump performance and hospitals need to weigh the risks versus benefits of keeping pumps outside of COVID-19 patients’ rooms.

“We would never imagine that this would be adopted as a go-to” solution other than in this “unusual pandemic situation — this is not ideal,” said the watchdog's director of consulting services, Michelle Mandrack.

According to ISMP, the length and inner diameter of long extension tubing can impact flow rates and the time medications and solutions take to reach a patient without flushing.

In addition, Mandrack warned that occlusion alarms may be delayed at low flow rates and more frequent alarms can occur at high flow rates. She also noted that the long tubing can contribute to the delay of infusion titration by nursing staff.

It’s a concern shared by the Surviving Sepsis Campaign, an organization initiated in 2002 by the European Society of Intensive Care Medicine, which has warned that placing infusion pumps in hallways can result in delays and inaccurate delivery of drugs. In particular, the group argues that the long tubing makes it impossible to titrate drugs based on a patient’s response.

“The nurse may titrate the drug on the pump after assessing the patient’s vital signs on the monitor. However, the drug may take hours to reach the patient,” according to the Surviving Sepsis Campaign. “Not realizing the drug is still in the tubing, the nurse adjusts the rate again. At some point, the drug finally reaches the patient and when it does, it could be too high or too low based on the patient’s physiological state.”

Similarly, an alert issued earlier this month by the ECRI Institute concluded that not all patients may be suitable candidates for delivery with a long extension set.

According to ISMP, the decision by hospitals to position infusion pumps in hallways is not an easy one. "At the same time, this measure is working at some hospitals that have decided that the risk is worth the benefit," the group concluded earlier this month in reporting the clinical experiences of two healthcare providers.

And the rising adoption of this workaround has led to yet another shortage, of the tubing extensions sets themselves.

“The use of extension sets has skyrocketed. Surely, product vendors did not anticipate that pumps would be moved to hallways,” observed Mandrack. “Some extension sets are on back order. Others have been allocated for previous or current customers.”

She noted an example of one hospital that “needed to reverse” its decision to locate infusion pumps in hallways and ended up returning them to patient rooms “because it couldn’t manage with the limited extension tubing availability.”

Nonetheless, B. Braun’s Karpf said the company has "identified IV extension sets that can be used for this purpose and have increased production accordingly."