Dive Brief:

-

Philips has formed manufacturing partnerships with manufacturers Flex and Jabil and launched a scaled down ventilator to help meet soaring demand for respiratory support equipment amid the coronavirus pandemic.

-

The Dutch conglomerate Tuesday said Flex and Jabil will use their production lines to respectively make its Trilogy and Respironics V60 hospital ventilators. Separately, Philips won emergency use authorization for its new stripped-down Respironics E30 ventilator.

-

Philips plans to make 15,000 Respironics E30 units a week starting this month. With the support of Flex and Jabil, Philips’ output of fully featured hospital ventilators is set to ramp up from 500 a week in January to 4,000 a week in the third quarter.

Dive Insight:

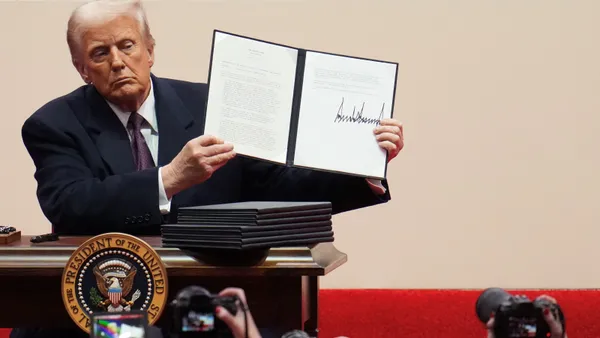

Governments around the world are racing to source ventilators to ensure COVID-19 patients can get the respiratory support they need. In the U.S., that effort manifested in a $647 million contract for Philips to supply 43,000 ventilators by the end of the year.

Having disclosed the contract last week, Philips has now detailed how it is ramping up production of ventilators. Like some other medtech companies, Philips has enlisted the support of third parties.

Flex and Jabil are manufacturing companies that work with businesses in medtech and a number of other industries including the automotive and energy sectors. Philips has tasked Flex with making its Trilogy hospital ventilator, adding to the capacity at its own Pennsylvania production plant. Jabil and a Philips plant in California will make Respironics V60 hospital ventilators.

Philips began ramping up its internal output from a baseline of 500 ventilators a week earlier in the year. Enlisting the help of Flex and Jabil is intended to support a four-fold increase in output by the third quarter.

Yet, even if Philips hits that target hospitals may still struggle to source sufficient ventilators. Philips said its fully featured hospital ventilators contain upward of 650 components. The complexity of the devices makes assembly a challenge and raises the risk of production being restricted by a shortage of one or more components. In a separate statement, Philips called the supply of components “the rate-limiting step,” adding that ongoing shipments require “the support of all countries involved.”

In light of the difficulty of scaling production of its hospital ventilators, Philips has designed and been granted authorization to provide a simplified emergency use ventilator. The ventilator is designed to be made at scale, enabling the company to predict that output will hit 15,000 units a week this month.

The design also reflects the times when the ventilator is likely to be used. Philips has simplified the process of setting up and operating the device to enable “healthcare providers with a wide range of skill sets” to treat patients. That reflects the fact the device will only be used when all conventional ventilators, and potentially all people specialized in their use, are occupied. The intended uses of the device cover the care of people in motels and other spaces temporarily converted into COVID-19 treatment centers.

Philips is one of a number of companies that is ramping up ventilator production. GM, which is partnered with Ventec Life Systems, has received a government contract to supply 30,000 ventilators.

The Department of Health and Human Services late Monday detailed seven new contracts for ventilator production totaling more than $1.43 billion, five of which are rated under the Defense Production Act. The DPA contracts went to GE, Hillrom, Medtronic, ResMed and Vyaire, with two other contracts awarded to Hamilton and Zoll.