Dive Brief:

- Advances in bioprinting technology could one day enable production of fully functional replacement organs from the cells of people in need of a transplant, Francis Collins, director of the National Institutes of Health, said in a new blog post.

- Collins pointed to the work of a bioengineering research team at Rice University in Houston that developed a process for bioprinting the small air sacs in the lungs.

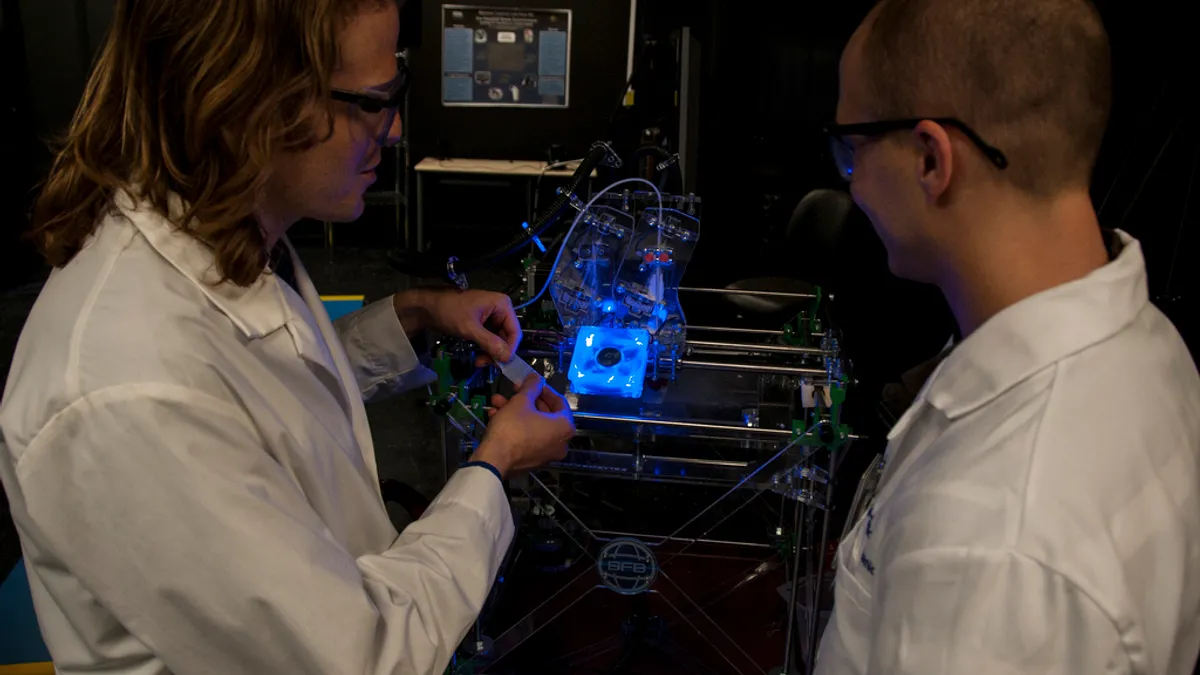

- The NIH-supported team created an open-source bioprinting technology that grows soft hydrogel scaffolds through printed layers to create complex 3D structures within minutes. Their research was recently published in the journal Science.

Dive Insight:

The process of 3D printing involves production of three-dimensional objects using a digital file. The printer layers images or files on top of one another until a solid 3D object is formed. The 3D models of a patient's anatomy can be used in diagnosis or surgical planning, or to customize devices such as orthopaedic implants, prosthetics, hearing aids and dental implants.

Major medical device companies including Stryker and Medtronic are looking at 3D printing to improve manufacturing efficiencies and product design. Sensors developer TE Connectivity's medical products group is also working on the technology.

More than 100,000 people are on the national transplant waiting list in the United States alone and 20 people die each day waiting for a transplant.

Collins pointed out that a major hurdle to growing fully functional replacement tissues and organs is finding a way to feed the growing tissues with a blood supply and to remove waste products. The Rice researchers were able to create an open-source bioprinting technology that "grows" soft hydrogel scaffolds one layer at a time.

Called stereo-lithography apparatus for tissue engineering, or SLATE, the system prints each layer using a liquid pre-hydrogel solution that solidifies when exposed to blue light. Projecting light into the hydrogel as a pixelated 3D shape enabled the printing of complex 3D structures within minutes, Collins said.

To make the printout process work for generating intricate vascular networks, researchers including Bagrat Grigoryan, Jordan Miller, and Kelly Stevens, substituted synthetic and natural food dyes widely used in the food industry for the highly toxic chemicals used in other manufacturing arenas to facilitate the conversion from liquid to solid in a fine polymer layer.

The research showed that the fully biocompatible dyes were effective light absorbers which allowed the scientists to recreate the complex architectures of human vasculature, and living cells survived within the soft scaffold, Collins said.

"With the aid of bioprinting advances like this one, perhaps one day we’ll have a ready supply of perfectly matched and fully functional organs," Collins wrote.