Dive Brief:

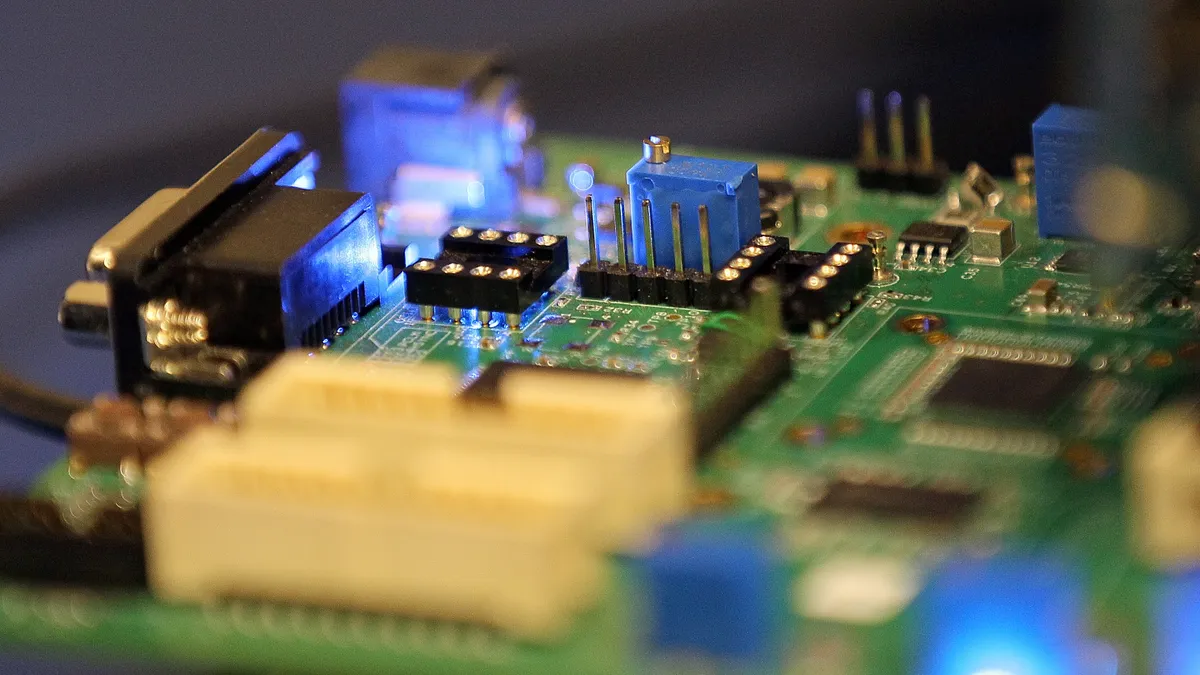

- Medtech manufacturers have become more pessimistic about the semiconductor shortage, with respondents to a Deloitte survey predicting the disruption to continue into next year.

- Commissioned by AdvaMed, Deloitte surveyed the industry in July 2021 and again in April 2022. The second survey found almost 80% of respondents are experiencing extended lead times and hospitals and health systems are looking into alternative products as a result of the disruption.

- Faced with the supply constraints, all respondents are pursuing alternative sources, having often relied on single semiconductor providers in the past, and 70% have increased inventory levels.

Dive Insight:

The July 2021 survey provided data to quantify the reports of semiconductor shortages, revealing delays ranging from two weeks to more than one year. Competing with tech companies and automakers for the chips, the respondents reported delays, reduced order quantities, order cancellations and substitutions.

Deloitte’s follow-up survey found that “medtech manufacturers had grown more pessimistic,” with many respondents reporting that “their inventory has since been depleted.”

The inventory depletions led the manufacturers to reduce or pause production, Deloitte found. More than 75% of respondents said their customers “have turned to alternative types of treatment.”

Manufacturers have acted to mitigate the threat to their businesses, making changes intended to shore up their supply chains. More than half of the polled companies used to rely on a single source for 75% of their semiconductor supply. All of the respondents now have multi-source strategies.

“Our members are developing lifesaving and innovative treatments for patients, and without the necessary components, it is becoming difficult to get these products into the hands of health care professionals,” AdvaMed CEO Scott Whitaker said in a Wednesday statement. “A failure to strengthen the chips supply line to medtech companies could result in a shortage of the medical devices and technology that millions of patients rely on every day, resulting in a crisis on par with what we are seeing with baby formula right now.”

One-third of respondents have connected with brokers to source semiconductors. Manufacturers used to “have little need for brokers,” Deloitte said, but they now offer an alternative way to source chips and “can provide safeguards against counterfeits.” Respondents told Deloitte counterfeits have become more of a challenge since the first survey.

Manufacturers are also establishing buffers against supply disruption. The proportion of respondents that have a chip inventory has risen from 13% before the pandemic to more than 70% in the latest poll.

The actions have potentially positioned the industry to weather what could prove to be a protracted crisis. Deloitte said “some respondents indicated they do not expect supply chain issues to improve before the first quarter of 2023.”