Trade group MedTech Europe is raising fears that lack of harmonized Medical Device Regulation standards will result in inconsistent and arbitrary application of the rules.

The warning, in a position paper posted Tuesday, coincided with publication of a volley of guidance documents covering different aspects of MDR and comes with just over two months before the May 26 go live date.

With the European Commission apparently intent on forging ahead with plans to implement the new regs in May — despite the coronavirus outbreak further complicating the situation — the medtech industry is working to identify and mitigate potential threats that may arise as a result of the change in regulatory regime.

MedTech Europe zeroed in on the lack of harmonized standards under MDR as among the problems its members may face.

European manufacturers favor use of harmonized standards “given their legal value in providing a presumption of conformity with the General Safety and Performance Requirements of the respective legislation," the group wrote. That preference creates a problem as, in the view of MedTech Europe, it is “questionable” whether harmonized standards will be available in time.

Fearing the lack of such standards will cause an “inconsistent and possibly arbitrary approach to the application of standards as a reference and benchmark for safety and performance,” the trade group is working with its members to create a set of criteria that manufacturers can use in the event the EU fails to firm up its position in time.

The paper features a hierarchy of standards, topped by previously harmonized standards under the outgoing EU regulations, that manufacturers can use in the absence of MDR-specific materials. In the absence of previously harmonized standards, MedTech Europe is advising manufacturers to make use of ISO standards and other international and European materials. The position paper features a list of such standards manufacturers can use to fill gaps in the library of previously harmonized standards.

MDCG shares guidance on medical software

MedTech Europe published its position paper around the same time the European Commission's Medical Device Coordination Group released another batch of guidance documents. MDCG held a virtual meeting last week, having scrapped plans to meet face to face in light of the coronavirus, and has subsequently shared a series of documents about MDR.

The most substantial of the latest crop of MDCG documents covers the clinical evidence companies need to generate to meet requirements MDR and its in vitro diagnostic counterpart, known as IVDR, place on medical device software. MDR requires companies to provide clinical evidence that is “appropriate in view of the characteristics of the device and its intended purpose” but lacks details about what that means in practice for software developers.

MDCG’s guidance aims to address that gap. The guidance states that software is subject to the same clinical and performance evaluation principles as physical devices and IVDs, but also provides details specific to software, notably in an annex that gives examples of evidence strategies suitable for different types of products.

For example, the developer of software to analyze sleep quality data may review the literature to establish a valid clinical association between a device and “clinical condition or physiological state.” The company would then need to run tests to show the software “can reliably and reproducibly calculate sleep quality scoring” and is compatible with the sensing device that gathers the sleep data. MDCG would also expect the company to run a retrospective study on sleep data.

Implant cards, Class I devices and the UDI system

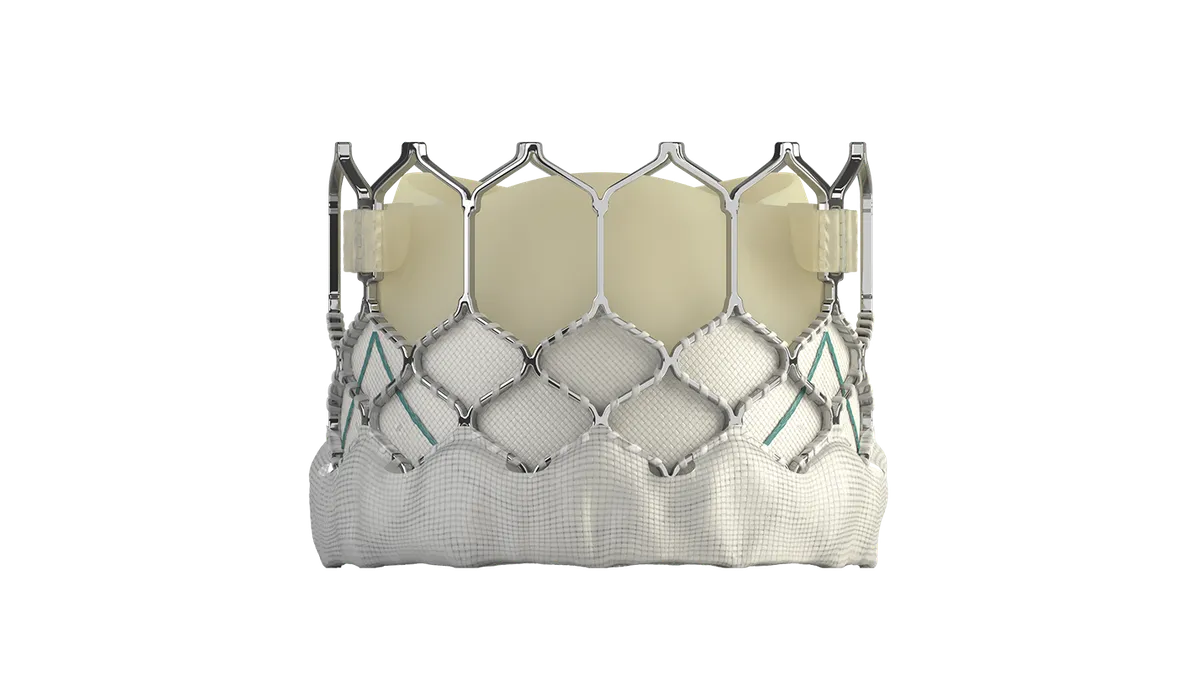

MDCG published the software guidance the day before issuing another substantial document about implant cards. MDR requires manufacturers to provide cards that describe the intended use of their implants. The cards are intended to ensure patients and emergency clinical staff who treat them are aware of the presence of implants and can access information about them.

In the guidance, MDCG lists the information manufacturers must provide on cards and recommends the use of symbols to avoid the need for nation-specific versions. However, the guidance lacks an accepted symbol for “device type,” leading MDCG to propose including that information in different languages.

The software and implant guidance documents became available concurrently with two shorter texts about the transition arrangements for Class I devices and the unique device identification system. In the Class I guidance, MDCG outlines the conditions manufacturers of Class I devices need to meet to benefit from the expansion of the transition period to cover their products. Manufacturers need to draw up a Declaration of Conformity by the time MDR is implemented in May.

In the other guidance, MDCG describes the basic UDI (unique device identifier) that connects devices with the same intended purpose, risk class and characteristics, and explains how they link to certificates and declarations of conformity.