UPDATE: Aug. 17, 2023: An Integra spokesperson said the company has accelerated upgrades to its quality manufacturing system in Boston.

"We will not resume production until we have addressed the FDA concerns and are confident the facility meets the strictest regulatory and product quality standards, which we anticipate will occur by the end of the calendar year," the spokesperson wrote in an email.

Integra LifeSciences received a warning letter from the Food and Drug Administration related to quality issues at its Boston facility after pausing manufacturing at the site.

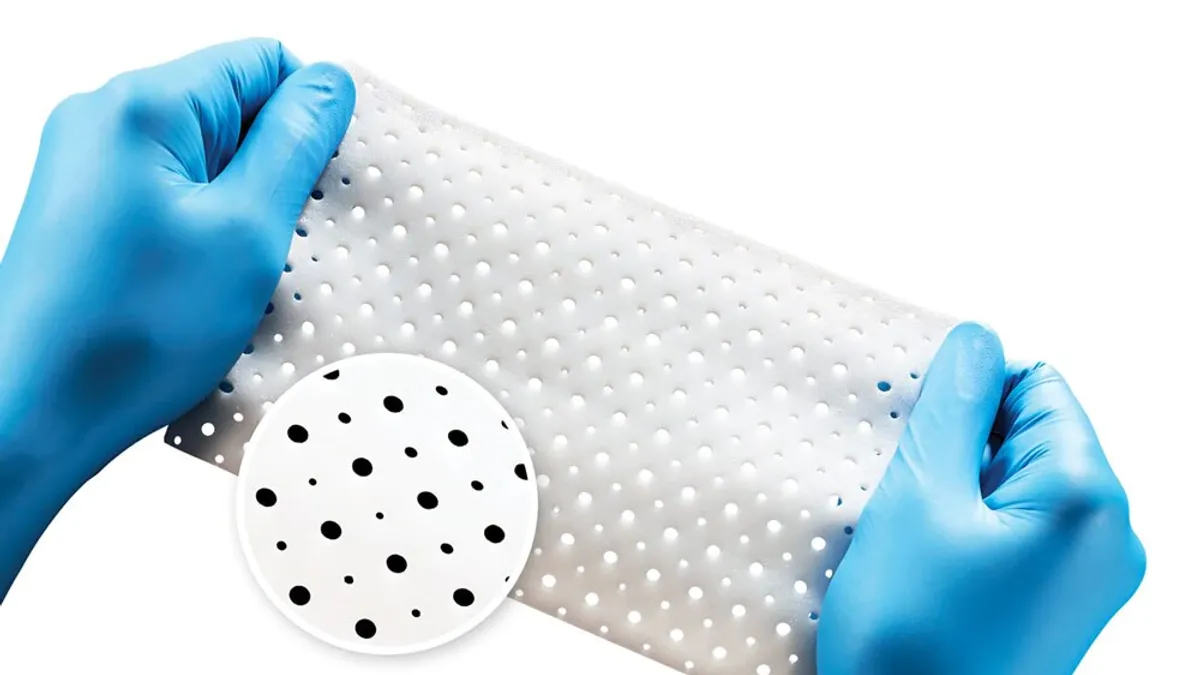

The letter, which was issued in July and posted to the FDA’s website on Tuesday, focused on problems at the plant that makes collagen-based medical devices for wound care, soft tissue repair and reconstruction surgery.

The FDA’s complaints included failing to implement corrective actions after a problem was reported, and handling sterilized devices in the same area as non-sterile product. In particular, the warning letter focused on how Integra handled issues with Durepair, a collagen matrix applied during neurosurgery procedures that the company manufactures for Medtronic.

For example, in 2019 Integra released one lot of Durepair that exceeded its threshold for bacterial endotoxin, which can cause postoperative fever, according to the FDA’s warning letter. The company said the problem was due to a transcription error.

Integra paused production at the facility in December 2022 due to an internal complaint about quality issues related to the inspection process, bacterial endotoxin testing, bovine hide or skin thickness measurement and control of sterilized devices. It initially did not address the endotoxin issues in a corrective action plan, the FDA said.

During the FDA’s inspection earlier this year, Integra started a health hazard evaluation to address the endotoxin concerns, but it was not comprehensive and did not include two complaints of meningitis associated with Durepair, according to the warning letter.

“We understand that you have taken a series of corrective actions, including a recall and production hold, however your response does not indicate how you will prevent such errors from recurring when you resume operations,” the letter stated. “In response to this Warning Letter, you will need to provide evidence that an effective and sustainable [corrective and preventive action] system will be implemented at your firm.”

Integra announced in May that it was recalling all products made at the Boston facility over the last five years after discovering a quality problem that could result in postoperative fever. The company said it would pause manufacturing until it could put in place additional quality controls.

It expected a $22 million impairment charge from writing off inventories of affected devices, including its SurgiMend, PriMatrix, Revize and TissueMend products.

In an earnings call last month, CEO Jan De Witte said the company hopes to restart manufacturing at its Boston plant during the fourth quarter of 2023, and start commercial sales in the second quarter of next year.

The full recall is expected to affect Integra’s revenue by $60 million in 2023, and by $50 million in 2024, BTIG analyst Ryan Zimmerman wrote in a research note on Wednesday. He questioned whether Integra can get its tissue manufacturing business back in the timeline outlined by management, noting that the warning letter requires Integra to fix a number of violations and certify an outside consultant's findings by March 31, 2024. Further observations and certifications are required in 2025 and 2026.

Currently, there are two audits of the Boston facility underway, J.P. Morgan analyst Robbie Marcus wrote in a research note in July. One of the audits is being conducted by third parties on behalf of Integra, and is related to restarting production at the facility in general. The second audit is about premarket approval for future products through the FDA.

The warning letter follows a previous one Integra received in 2019, also related to the Boston facility.