Dive Brief:

-

GE Healthcare and the Department of Veterans Affairs have partnered to cut the time it takes radiologists to create 3D-printed models and prosthetics.

-

Through the agreement, GE will provide VA Puget Sound Health Care System with software and workstations to automate some of the tasks involved in the creation of 3D models.

-

The partners claim automation could cut the time it takes radiologists working in cardiology, oncology and orthopaedics to create 3D models from hours to minutes.

Dive Insight:

The 3D printing of medical devices, also known as additive manufacturing, is set to grow into a $1.88 billion market by 2022, according to MarketsandMarkets. That figure reflects the fact the field is still in its infancy. In the longer term, 3D-printed devices could disrupt many major markets by enabling the creation of implants tailored to the anatomies of individual patients.

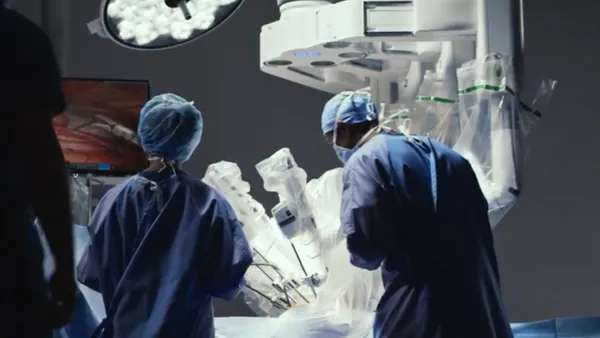

At VA, the technique is being used by radiologists to aid the visualization of patient anatomy. While these radiologists can already view images in 3D on computer screens, they see value in generating physical models of these scans.

“By harnessing the power of 3D printing with a rich data set, we are able to pull images out of the screen and into our hands, allowing us to interact with the data in a deeper way to fuel innovative, personalized care based on the unique needs of each of our patients,” Beth Ripley, a radiologist at VA Puget Sound, said in a statement.

Applications of 3D printing in this context include the production of plastic models of the hearts of patients due to undergo surgery. The models help surgeons view the coronary vessels and plan their procedures based on the actual anatomy they will encounter.

VA’s work in the field to date has relied on 3D software originally designed for use outside of the medical sector. By partnering with GE, VA has gained access to workstations and 3D printing software tailored to the needs of radiologists and other healthcare professionals.

Once installed at its facilities in Seattle, San Francisco, Minneapolis, Cleveland and Salt Lake City, VA thinks the GE systems will enable radiologists specializing in cardiology, oncology, orthopaedics and other areas to quickly generate 3D models. The envisaged time savings stem from the automation of tasks involved in the pre-3D printing preparation of models of normal and pathological anatomy.

If the system performs as hoped, the partnership will provide validation of GE’s 3D printing software. GE moved into the field to improve on older systems, which required users to manually generate, convert and compress images into files readable by 3D printers. By integrating its 3D software with its existing workstations, GE sought to enable users to quickly translate imaging data into printable files.