Dive Brief:

-

The Department of Health and Human Services has given General Electric, working with auto giant Ford, a $336 million contract to supply 50,000 ventilators by mid-July under the Defense Production Act, the 1950 law empowering the president to require companies to prioritize and accept contracts for materials and services during national emergencies.

-

GE and Ford are making a simplified ventilator based on a design licensed from Airon. HHS earlier this week detailed a separate contract with GE worth $64 million for 2,410 ventilators produced by June 29.

-

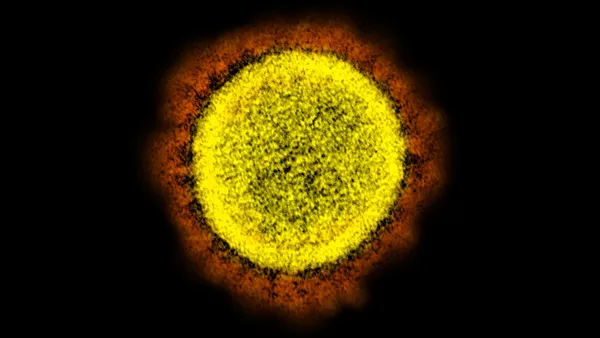

The HHS contract disclosed Thursday comes amid a slew of deals detailed this week for the complex breathing machines required by severely ill COVID-19 patients, including with General Motors, Philips and Medtronic.

Dive Insight:

Landing the deal brings business into GE Healthcare as the coronavirus pandemic is hurting the unit and the broader conglomerate. In recent weeks, GE has warned deferred procedures are affecting its healthcare business and withdrawn its financial guidance.

Last week, GE warned first quarter earnings look set to come in “materially below” its earlier forecast. The company did not fully unpack the reasons for the earnings miss, but previously cited its healthcare and aviation units as among the businesses negatively affected by the pandemic.

Faced with the prospect of ongoing disruption, GE moved earlier this month to reduce its debt. The flurry of financial actions included the use of $6 billion from the sale of GE’s biopharma business to repay a loan.

GE will share a full look at its financial situation on an earnings call April 29 but has already provided pointers. In keeping with the situation at companies including Johnson & Johnson, GE Healthcare has seen “reduced demand for certain equipment as elective procedures are postponed or canceled around the world.”

However, unlike with aviation, the pandemic also creates some tailwinds for the healthcare unit. GE highlighted the need for more CT scanners, ultrasound devices, mobile X-ray systems, ventilators and patient monitors among the effects of COVID-19 on its healthcare business.

The push to increase ventilator output has advanced on two fronts. The company was already making a ventilator, the CARESCAPE R860, when the pandemic hit. However, like other fully featured hospital ventilators the R860 is a complex device. That affects the rate at which GE can manufacture the device and the price at which it can sell it.

To increase output, GE licensed the design of an FDA-cleared ventilator from Airon and tasked Ford with making the device at a components plant in Michigan. The ventilator functions without electricity and operates on air pressure.

With Ford aiming to make 50,000 of the ventilators by July 4, HHS has tasked the automotive company with meeting the near-term need for respiratory support equipment. The contract calls for GE and Ford to provide 50,000 ventilators by July 13. Philips, in contrast, is expected to provide 43,000 ventilators by the end of the year.

The contract awarded to GE and Ford works out at $6,720 per ventilator. Philips and GM are set to receive around $15,000 and $16,000, respectively, for each ventilator they provide to the national stockpile based on the contract sizes.

GE's $64 million contract from earlier this week for 2,410 ventilators works out to about $26,000 per ventilator.

News of the ventilator contract arrived a day after GE provided an update on its collaboration with Microsoft. GE Healthcare is providing its Mural Virtual Care Solution on the Microsoft Azure cloud platform. The software is designed to support centralized monitoring of intensive care patients, such as people with COVID-19 who require mechanical ventilation.